POST-COATING INSPECTION AND MAINTENANCE

Once the powder coating process is complete, it’s essential to conduct thorough inspections and implement regular maintenance practices to preserve the integrity and longevity of the coated items. Here’s why post-coating inspection and maintenance are critical, along with best practices for ensuring optimal performance and durability:

ENSURING QUALITY ASSURANCE

Post-coating inspection serves as a crucial quality control measure to verify that the powder coating has been applied correctly and meets specified requirements. By identifying any defects, imperfections, or inconsistencies early on, necessary corrective actions can be taken to uphold quality standards and customer satisfaction.

DETECTING DAMAGE OR WEAR

Regular inspections allow for the early detection of any signs of damage, wear, or deterioration in the powder coating. This includes scratches, chips, fading, corrosion, or adhesion failures that may compromise the protective barrier and aesthetic appearance of the coated surface.

PREVENTING FURTHER DETERIORATION

Addressing issues promptly is key to preventing further deterioration and extending the lifespan of the powder coating. Timely intervention can mitigate the risk of corrosion, substrate damage, or contamination, preserving the integrity and performance of the coated items over time.

MAXIMIZING LONGEVITY AND PERFORMANCE

Proper maintenance practices contribute to the longevity and performance of the powder coating, ensuring continued protection against environmental factors, chemical exposure, UV radiation, abrasion, and mechanical stress. Regular inspections and maintenance help uphold the coating’s aesthetic appeal, functionality, and durability over its service life.

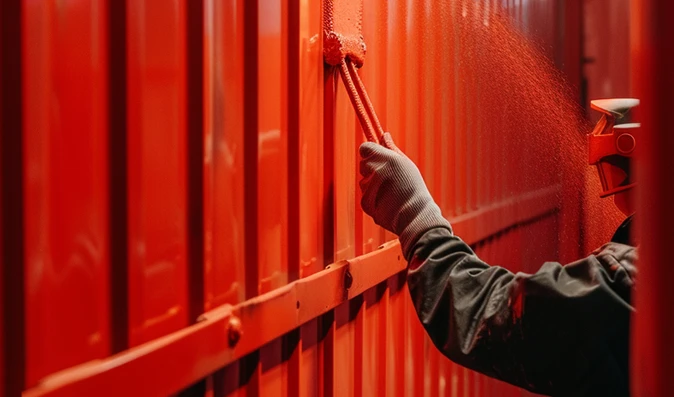

CONDUCTING ROUTINE INSPECTIONS

Schedule regular inspections of powder-coated items to assess their condition and identify any areas of concern. Inspect surfaces for signs of damage, wear, or defects, paying attention to high-stress areas, exposed edges, and vulnerable components prone to wear and tear.

ADDRESSING ISSUES PROMPTLY

Upon detecting any issues during inspections, take immediate action to address them to prevent further deterioration or damage. Depending on the severity of the issue, this may involve repairing damaged areas, recoating affected sections, or implementing protective measures to prevent recurrence.

IMPLEMENTING PREVENTIVE MAINTENANCE

In addition to reactive maintenance, implement proactive preventive maintenance measures to safeguard powder-coated items against premature degradation or failure. This includes routine cleaning, corrosion protection, lubrication of moving parts, and environmental protection measures.

CONSULTING WITH COATING EXPERTS

Seek guidance and advice from experienced powder coating professionals regarding post-coating inspection and maintenance practices. They can provide valuable insights, recommendations, and solutions tailored to specific coating systems, substrates, and environmental conditions.